INNOVATEST hardness testers can be supplied with external desktop computers or workstations. We leave it to your consideration as long as the computer supplied meets the minimum requirements to operate our machines properly.

INNOVATEST strongly recommends the use of our standard embedded Industrial Windows controller, let us explain why:

Benefits of an Embedded Industrial Computer

The embedded industrial computer plays a crucial role in the fields of pharmaceutical, medical, food, service industries and the military, to name only a few. Here’s a closer look at some of the superior advantages that embedded industrial computers have over their general desktop or workstation counterparts;

Performance efficiency – In an embedded industrial computer, there is generally a single function for that device. For example, an embedded industrial computer for a traffic signal matrix has the hardware and software dedicated to the proper functioning of that particular purpose alone; hence there is an optimization of what the product can do. You need to ask yourself the question, would you wish to operate a rocket launcher from a desktop work station that has word, excel or games installed? No? At Innovatest we have the opinion that machines and or other quality equipment should be operated from a controller that has one task only, excellent machine performance with high reliability.

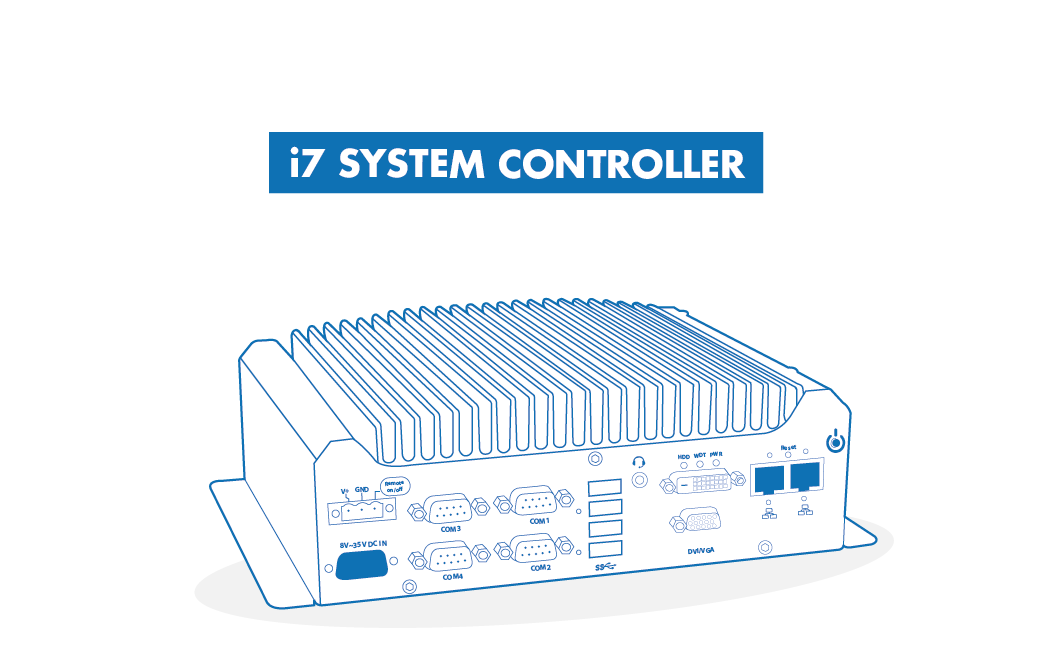

Product reliability – Given that an embedded industrial computer is potentially exposed to harsh conditions, and is certainly relied upon to accomplish its task without failure, manufacturers will often add certain features such as an SSD, for fast, reliable data storage, a watchdog timer and design it for fanless operation to eliminate the risk of failure due to moving parts or overheating. Mechanical heat sink as applied in all Innovatest machines eliminates any heat problem.

Durability – Many embedded industrial computers are used directly in factories and other harsh environmental settings which may not only expose them to harsher conditions, but also involve situations of rough handling for these electronics. Embedded industrial computers, depending on their use, are built to withstand fairly severe environments. They can be made to absorb stationary shocks or falls, remain functional even when in transfer via vehicles and are due to their location protected from exposure to moisture and dirt such as by conformal coating of the motherboard.

Longer product life cycle – For most embedded industrial computers, the regular life span of a model is estimated at approximately seven to ten years. Manufacturers design their boards with long life chipsets, assuring that the unit is meant to last. This is 3x better than the life span expectation of desktop work station.

Customizable features – Compared to general-purpose computers, which have an array of basic functions and features that cater to most office needs but have no use in industrial equipment, an embedded industrial computers has 2 main functions only. These are operation, control and data collection of industrial equipment through the specialized software to operate such equipment. With either one of these purposes in mind, nearly anything can be done with the hardware, then the OEM manufacturer, like Innovatest can further customize the unit to accommodate the needs of their particular industry or job by installing their proprietary software like IMPRESSIONS™.

INNOVATEST hardness testing equipment has Embedded Industrial Computers as standard controllers on board of all our IMPRESSIONS™ operated hardness testers.

So, can INNOVATEST IMPRESSIONS™ software run on a standard Hewlett Packard, Dell, or another A class desk top work station? Yes it can, we just don’t recommend it, for the above reasons.